Aluminum foil has become a staple in most kitchens worldwide. Its remarkable versatility enables it to be applied for a wide range of tasks, from preserving food to cleaning surfaces. This lightweight and durable material frequently serves as a substitute for other materials in innovative projects.

- Think about using aluminum foil to line your baking pans for effortless cleanup.

- Protect leftovers in aluminum foil to keep them fresh

- Build your own reflector for your plants by setting aluminum foil around them to boost light reflection.

Understanding Aluminum Foil Paper and Its Applications

Aluminum foil paper, a functional material known for its glistening surface, has become an integral part of our daily lives. Its remarkable attributes, including malleability, make it ideal for a wide range of applications.

From domestic uses like wrapping food to more specialized applications in the commercial sector, aluminum foil paper plays a crucial role. Its ability to absorb heat and its durability make it an invaluable tool in various fields.

Some common applications of aluminum foil paper include:

* Insulating food from spoilage and moisture

* Redirecting heat in cooking and baking

* Creating makeshift emergency reflectors for signaling

* Patching minor leaks in pipes or containers

* Storing sensitive electronic components

Aluminum foil paper's convenience, coupled with its adaptability, ensures its continued relevance in modern society.

Choosing the Right Aluminum Foil Container for Your Needs

When it comes to storing leftovers or preparing meals in the kitchen, choosing your right aluminum foil container can make all the difference. With a variety of shapes and features available, finding the perfect match for your requirements is essential.

Consider elements such as the quantity of food you'll be storing, whether you need a washable container, and if you require a container that is microwave or freezer safe.

An well-constructed aluminum foil containers can provide excellent insulation and, keeping your food warm for longer periods of time.

Before you make a purchase, take the duration you'll be using the container for in addition to any special specifications you may have.

Productivity and Improvements in Aluminum Foil Container Making Machines

The aluminum foil container industry is regularly progressing at a rapid pace. Manufacturers are continuously seeking ways to improve the efficiency and advancements of their machines. This focus on enhancement is driven by the need for quicker production speeds, lower operating costs, and improved product quality.

Recent technologies are utilized to achieve these goals. For example is the integration of advanced automation systems that optimize the manufacturing process. These systems can independently modify machine settings based on real-time information, leading to increased precision.

- Moreover, the use of smart sensors and software allows for continuous observation of machine efficiency. This enables manufacturers to rapidly detect potential issues and make corrective actions to prevent downtime.

- Moreover, research and development efforts are concentrated on creating new materials and manufacturing processes that improve the strength, durability, and environmental impact of aluminum foil containers.

In conclusion, the combination of efficiency and innovation is essential for the continued success of the aluminum foil container industry. By embracing these advancements, manufacturers can meet the expanding demands of consumers while lowering their environmental effect.

Exploring the Manufacturing Process of Aluminum Foil Containers Examining the Production of Aluminum Foil Containers

The manufacturing process of aluminum foil containers is a fascinating blend of mechanical engineering and material science. It all begins with large sheets of aluminum sheet metal, which are then fed into specialized machines called rolling mills. These mills apply immense pressure to the aluminum, reducing it to an incredibly thin gauge. The resulting foil is remarkably resilient and possesses a high degree of flexibility, essential qualities for forming into containers.

Next, the aluminum foil undergoes a series of intricate steps to create the final product. Cutting machines precisely cut the foil into the desired container shapes, whether it be rectangular trays, cylindrical cups, or even complex molds for specific applications. Thereafter, these containers are subjected to a heat treatment process, which enhances their strength and durability.

Finally, the aluminum foil containers may undergo additional processes like coating with a protective layer or printing with logos or branding. This ensures that the containers are both functional and visually appealing, ready to hold a wide range of food items for storage, transport, and even consumption.

Trends in Aluminum Foil Container Manufacturing

As industry expectations for sustainable and innovative packaging solutions continue to escalate, the future of aluminum foil container production is poised for significant transformations. Innovative manufacturing processes are expected click here to play a fundamental role in shaping this evolution, leading to more efficient production processes and the development of cutting-edge container designs.

One key trend is the increasing adoption of automation in manufacturing operations. This will not only enhance production speed and accuracy but also reduce labor costs and carbon footprint. Furthermore, the research into sustainable aluminum foil materials is gaining progress, offering promising options for more environmentally responsible packaging.

- Reusability will remain a critical concern, driving the development of recycling systems for aluminum foil containers.

- Lightweighting will continue to be a focus, reducing material usage and fuel consumption.

The future of aluminum foil container production presents exciting opportunities for both the industry and consumers. By embracing innovation and sustainability, manufacturers can develop containers that meet the evolving needs of a environmentally aware marketplace.

Angus T. Jones Then & Now!

Angus T. Jones Then & Now! Bradley Pierce Then & Now!

Bradley Pierce Then & Now! Brandy Then & Now!

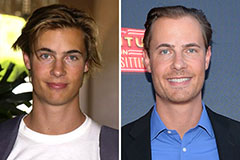

Brandy Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now!